Wine science researchers from the University of Adelaide have found that a tailor-made polymer developed in New Zealand could hold the key to removing smoke taint in wine.

Wines made from grapes exposed to smoke result in an acrid, ashy aroma, taste and mouthfeel that compromises quality and reduces value to the point that it is oftentimes unsaleable.

Ideally, to remediate smoke tainted wine, the molecules responsible need to be reduced, without removing desirable elements that contribute to the wine’s composition, colour and flavour.

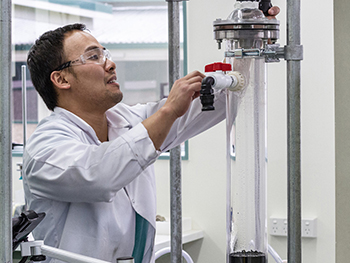

Professor of Oenology, Kerry Wilkinson, and her colleagues have successfully tested a method to lessen smoke taint in wine, validating the use of molecularly imprinted polymers (MIPs) to target removing the volatile phenols responsible for the smoke taint.

Researchers added MIP beads to smoke-impacted wine which selectively bound and removed the target compounds, ameliorating the wine’s sensory profile.

MIP specialists, amaea, developed the MIPs used in the Australian Government funded study.

“The selectively of MIPs made the science worth considering as a method to reduce volatile phenols,” says Kerry Wilkinson.

“We exposed the wine to MIP beads imprinted with billions of binding sites complementary to the target compound’s molecular properties, such as size, shape and chemical characteristics – which allows the MIPs to specifically target, capture and remove the offending phenols.”

The research showed the MIP technology was successful at removing 35−57% of the volatile phenols from the sample wines which included guaiacol, 4-methylguaiacol, cresols, and phenol.

The findings were recently published in ACS’ Journal of Agricultural and Food Chemistry: Amelioration of Smoke Taint in Wine via Addition of Molecularly Imprinted Polymers during or after Fermentation.

Dr Aaron Low, Chief Technical Officer amaea, says removing smoke taint from wine has long been a challenge for winemakers as often more is stripped away than desired.

“It’s great to see the results of this study as it provides further validation that our technology is effective for smoke remediation.

“Their research started in 2020 using one of amaea’s early generation MIPs and since then, our R&D team have advanced our MIP formulation and technology to refine its selectivity, and it is now being used by commercial clients.”

Dr Low says not every smoke-impacted wine is the same.

“The level of removal required not only relies on the MIP design but the way MIPs are applied. We’ve learnt that using our MIPs in a filtration system, with adjustable treatment rates, tailors the outcome.

“This means the volatile phenols can be reduced enough so that they sit below sensory thresholds, while the integrity of the wine’s varietal body and character can remain intact to suit geographical, market and brand preferences. Longitudinal studies also confirm smoke markers won’t return.”

Removing other wine taints with MIPs

Dr Low says that the ability to tailor the sensory profile of wines with MIPs opens up new opportunities.

“When you look at the chemistry of wine and the ability to remove target molecules, there is real opportunity for MIP applications to remediate taints beyond smoke.

“We have expanded our treatment profile to target pyrazines, ethyl phenols and phenolic compounds and are currently working on broadening this further.”

How to catch up with The Shout NZ…

Online, updated daily with its own unique content and breaking news.

Our weekly newsletter – free to your inbox! Subscribe here.

We are also on Facebook and Instagram!